This Guide to Practical Operational Amplifiers was written for a corporate R&D audience based on prior training I received, research I have performed into op amp performance, my experiences analyzing design tradeoffs, and results I have witnessed based on lab testing and simulations.

The guide will be presented here in the form of multiple blog posts and will cover everything from reading a datasheet and common circuits all the way through non-ideal effects such as stability, noise considerations, and input offsets. Throughout this guide the MC33172 op amp will be used as the example. Where appropriate, LTSpice circuit files will be provided that simulate the concepts presented in this guide.

Choosing the Right Op Amp

There are literally hundreds of Op Amps to select from. There is no one right answer, and it is based on the circuit application.

Some considerations (not in any particular order):

- Drive Current (sourcing/sinking)

- Reactive Drive Capability (Capacitance/Inductance)

- Bandwidth

- Slew rate

- Power Consumption

- Temperature Range

- Input Voltage Capability

- Output Voltage Swing

- Noise

- Voltage Supply Operating Range

- Phase Reversal

- Non-ideal DC Error Characteristics

- Stability

- Cost

- Availability

- Package

- Voltage Feedback (VFB) verses Current Feedback (CFB)

The challenge is finding the op amp that meets the requirements of the design, including those that you do not even know yet. How are you going to do it? A parametric search is often a good starting point. Many vendors have parametric search functions on their website; or, you can use a third party parametric search provider that aggregates multiple manufacturers (such as findchips.com).

Talking with the vendor directly is another option. Sometimes it is better to ask distributors rather than manufacturers. While a specific distributor may not carry every manufacturers’ line, manufacturers may frequently request information about the outcome of your part search and on the status of your project. There are lots of manufacturers of op amps. Be sure that the op amp you select can be purchased from an approved vendor.

Reading Datasheets

The datasheet contains a lot of important information, and every vendor writes their specifications slightly different. It is critical to be able to understand a datasheet and get the information that you need with the correct interpretation. Ask the vendor for more information when needed – but make sure you document anything that is not explicitly on the datasheet, along with the source of the information.

Here are some things to consider and watch out for.

The Front Page

The front page of the op amp datasheet contains marketing material. This material shows a selected portion of the truth and generally represents best case scenarios. It should not be blindly trusted for design and calculation purposes. Know the specifics behind each parameter.

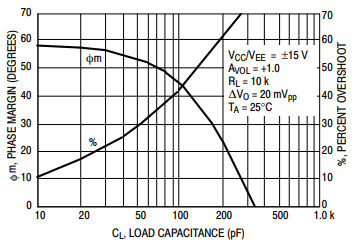

For example, consider the “excellent phase margin” statement from the front page of the MC33172 op amp datasheet as shown in the figure below. It states that the phase margin is 60°. However, if you look further into the datasheet, it is listed as 45° with a 100pF load and about 25° with a 200pF load.

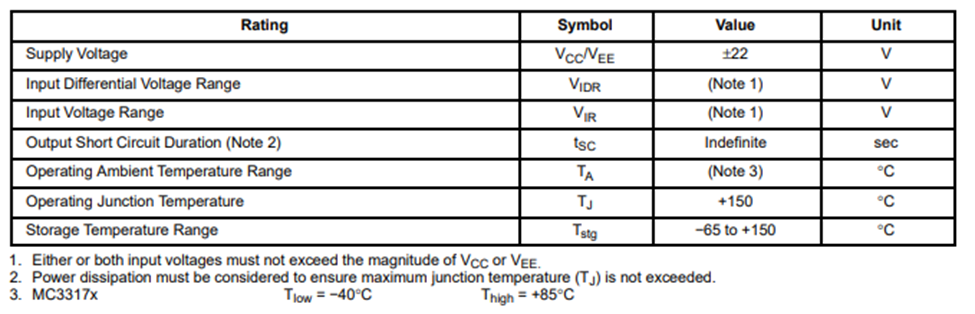

Maximum Ratings

All op amp datasheets will have a maximum ratings table. This table describes the stresses, that if exceeded, may damage the device. Both the operating and storage limits are listed. Never exceed the maximum ratings! If any of these limits are exceeded, the device functionality cannot be assumed and the reliability of the device may be compromised. The below table shows the maximum ratings of the MC33172.

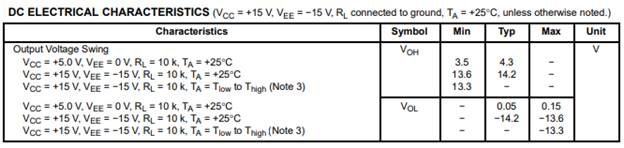

Electrical Characteristics Table

The electrical characteristics section of the datasheet quantifies the expected electrical operation of the device. The actual values for each characteristic will be listed as a minimum, typical, or maximum value. In addition, many notes and operating conditions (such as temperature or frequency) will be specified that restrict the validity of the listed information.

What if the specified operating conditions do not match your design or implementation? You may need to interpolate the characteristics to match your operating conditions. Sometimes it is possible to do so from the electrical characteristics tables. Other times, you may need look at the graphs included in the datasheet or contact the manufacturer.

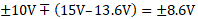

For example, in the DC Electrical Characteristics table below, the output voltage swing is listed for a specific supply voltage and load. If you are powering the op amp with a ±10V supply, you could reasonably conclude that the best case maximum output voltage range at room temperature would be about

In this case, if the design requires operating close to the supply rails, you may need to prove the design through prototyping or talk with the manufacturer to determine if the MC33172 would work.

When can you use the “typical” specifications for a design? In many circumstances, you cannot…

The typical specifications are not guaranteed, but are expected based on the model the manufacturer used for design and testing. They are useful for back-of-the-napkin calculations or where min/max values are not provided. For specifications that directly affect the output of the circuit stage in a calculable manner, typical specifications should not be used. These types of specifications include input offset voltage, input bias current, short circuit outputs, and power calculations.

Common Mode Rejection Ratio (CMRR), Power Supply Rejection Ratio (PSRR), phase margin, etc. might be able to use the typical value depending on the application. For specifications that are critical to the circuit’s operation, the min and/or max values should be used. If the min and/or max values are not obvious, it will be necessary to consult the datasheet graphs or confirm with the manufacturer. If they cannot or will not confirm a specification, you may need to select an alternate part.

Datasheet Graphs

When should you use information from a graph in the datasheet instead of from a table? Graphs are helpful for getting an idea of how a parameter changes over temperature, voltage, frequency, or some other variable parameter. Tables, on the other hand, generally contain a single value or limited range.

Let’s go back to the phase margin example. The front page lists 60° of phase margin. The AC electrical characteristics table lists

- 60° for a resistive load (RL) of 10kΩ,

- and 45° for a complex load of 10kΩ and 100pF.

The related graph in the datasheet (below figure) relates both phase margin (φm) and percent overshoot to the load capacitance (CL). Here you can determine phase margin (a predictor of circuit stability) for any load capacitance in your circuit. In this example, RL and the other fixed parameters are included as an overlay.

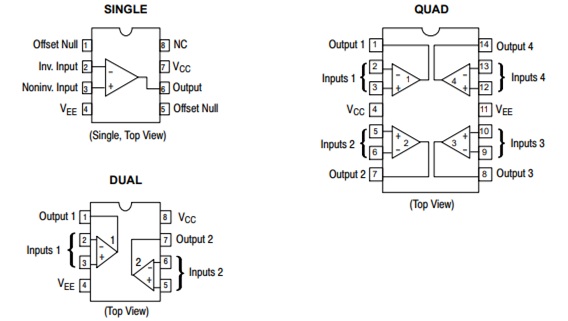

Device Pinout

Many classes of op amps have common pin connections for single, dual, and even quad packages. The pinout of the MC3317X for these packages is shown here.

Watch out for devices with a pinout that you don’t expect. It is advantageous to use common pinouts and footprints when selecting an op amp for a production design. An op amp may become obsolete or you may need to replace it for a different reason. It is easier to replace if the Printed Circuit Board (PCB) layout does not need to be changed. However, it can also be beneficial to select a different pinout or package for other layout reasons. Sometimes a different package (i.e. inputs and output on the same side of the package instead of the opposite side) is just what is needed to make a tricky layout work.

Application Information Section

Many op amp datasheets include an application section. Be sure to familiarize yourself with this section when becoming acquainted with a new op amp. Many important details that cannot be captured as a specification are included. Some things that may be discussed are performance features, PCB layout guidelines, bypass capacitor requirements, diode input protection, common use cases for specialty op amps, stability, and phase reversal.

When comparing op amps from two different vendors be sure to read through the application information sections of both if available. Even if the op amps are “identical”, there may be subtleties in part operation that can be easily missed.

Recommended Circuits Section

Some datasheets will include a section detailing recommend circuits for the selected op amp’s typical uses. For example, the MC33172 has multiple 5.0V supply amplifiers and a couple filter circuit schematics included in the datasheet. Having some circuits listed as a starting point may be nice, but do not use them without first understanding the design completely. Be sure to figure out all of the assumptions made by the datasheet author.

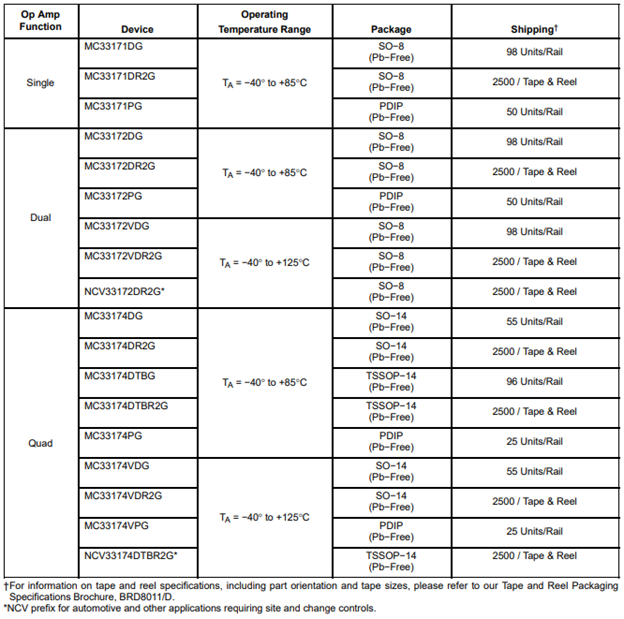

Ordering Information

Make sure that you are really ordering the part you are trying to order. Many vendors use complicated part numbering schemes where RoHS compliance and even the shipping packaging (tape & reel vs. cut tape vs. tray) information is a component of the part number.

As an example, look at below table to see how small changes in the orderable part number of the MC3317X series of op amps affect the temperature range, device package, and shipping packaging.

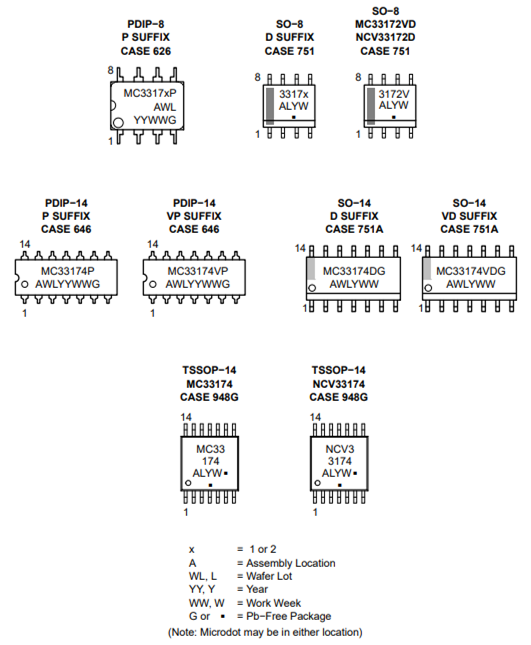

Marking Diagrams

Marking diagrams are extremely valuable when you are trying to find out what part is on a Printed Circuit Assembly (PCA). This is especially true now that part sizes are shrinking to the point that full part numbers cannot be printed on them. Often part numbers are abbreviated. Lot, manufacturing date, and lead-free status can also be shown.

Orientation information is also provided as part of the marking diagram. Many op amps (and other integrated circuits) indicate via a depression in the package or a printed marking which is pin number one. For hand assembly and for troubleshooting and testing purposes this is a valuable indicator that lets you quickly identify which pin is which.

Reference the below figure for the MC3317X op amp series marking diagram.

Package Dimensions

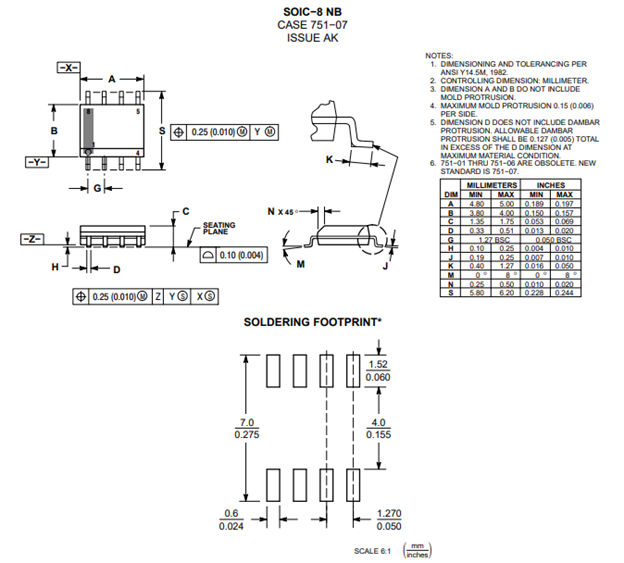

The package dimensions detail the physical size of the available package options. The physical dimensions will help you identify if the part will fit in a cramped layout, under a daughter card, or on the back side of the PCA for boards with components on both sides. It will also help identify if an alleged “drop in replacement” part is mechanically compatible.

Often a soldering footprint is included with or near the package dimensions. If a tested and approved footprint is not already available in your layout CAD software, the included footprint is a good starting point for a PCA engineer bringing in the new footprint or device. The below figure shows the SOIC-8 package dimensions for the MC33172 as a representative sample of the type of information to expect.

Comments are closed